Focke-Achgelis-EN

Focke-Achgelis

Focke, Achgelis & Co. G.m.b.H.

- Commercial Director: Dipl.-Ing. Kirchhoff

- Technical Director: Prof. Dr.-Ing e. h. Henrich Focke

- Plants: Hoyenkamp near Delmenhorst, Oldenburg, Laupheim

Henrich Focke was born on 8 October, 1890. In 1909, still at school, he was already working on the construction of flight models and gliders. In 1913, he began his studies at the Technical University of Hanover, which – interrupted by World War I – he finished after the war. After serving as an infantryman during the war, Focke was transferred to the Air Force and crashed at the Western Front in 1917. After the crash, Focke was stationed at the aircraft maintenance at Berlin-Adlershof. In 1923, he founded the Focke-Wulf Flugzeugbau AG together with Georg Wulf, who had been his assistant since 1913. Focke was technical director and member of the board until 1933. He was always used to cut his own path. So, in 1931, he purchased the licence of the Cierva autogyro and used the Focke-Wulf facilities to build the model C-19 Mark VI “Don Quichote” and later the C-30 “Heuschrecke” (“Grasshopper”). Motivated by the work on these rotary-wing aircraft, Focke established a research laboratory as part of his own factory in 1931 that later became his sole point of interest. This was the place where the Fw 61 was built. This research laboratory became the birthplace of Focke, Achgelis & Co. GmbH. In 1937, Prof. Henrich Focke founded the Focke, Achgelis & Co. G.m.b.H. together with the renowned stunt pilot Gerd Achgelis. Other members of staff were Dr. Jaeckel, Dr. Just, Dr.-Ing. Schweym, and Dipl.-Ing. Spanger. In the beginning, design and production was provided by the Brandenburgische Motorenwerke in Spandau, but was automatically transferred to BMW, after both companies had merged. Later, the entire development staff was separated from BMW at the instance of the Reichsluftfahrtministerium (Reich Air Ministry, RLM) and was made available to Focke-Achgelis. Initially, the work in this group was headed by Director Dipl.-Ing. Wolff, later, by his closest assistant, Obering. Bussmann, and Dr.-Ing. Löffler on the theoretical side. The Fw 61, being the world’s first successful helicopter, was followed by a number of other successful rotary-wing aircraft and some interesting projects that could not be completed because of the war.

Focke-Achgelis Fa 223

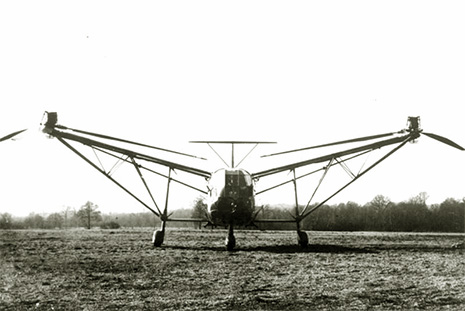

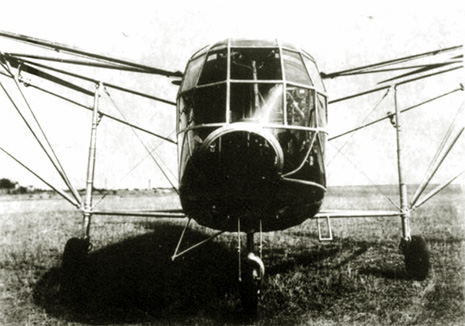

After the development of the Fw 61 German authorities agreed that a helicopter should be capable to carry a payload of 700 kg to be of practical use. This was the reason for the design of a substantially larger construction that started in 1938. The Fa 223 had fundamentally the same framework as the Fw 61. It was also equipped with twin-rotors mounted side-by-side on outriggers. One of the two Fw 61 was expanded to a flying laboratory in order to gain planning fundamentals for the Fa 223. The prototype of the Fa 223 left the factory in August 1939 and for the first time lifted off the ground in August 1940, still captured. 100 hours of ground testing had preceded the lift-off. The designers had to overcome a large number of problems: unbalanced rotors, developing safety devices for switching automatically to autorotation in case of a powerplant or gearbox failure, as well as solving the problem of blades being sensitive against a pitch-angle change and the problem of vibrations. During these tests the hazardous mutual self-excitation of the rotor blades was discovered. Subsequent flight testing had to be accomplished in hovering flight, due to the non-existing large wind tunnel, covering many aspects of lift, resistance and torque. At the beginning of 1942, the model was ready for serial production, and an order for 100 units followed. Because of the war and permanent bombing only 20 had been built by the end of the war, and only 10 of them had flown. At the end of the war, only two machines were found ready to fly. One of them was disassembled and shipped to the US, the other became the first helicopter to cross the Channel to England. The Fa 223 showed good flight characteristics and was fully stable around all axes with regard to statics and dynamics, except for stability around the pitch axis. During cruise flight at 140 km/h the stick could be released, because the instability around the pitch axis disappeared at approx. 120 km/h. 26 pilots were fully retrained to this type within 2 ½ to 3 ½ hours despite the dynamic instability of the flight. These tests covered flights with wind speeds of 21 m/s and extensive mountain testing in the Karwendel Mountains.

Type: Single-engine transport helicopter

Rotor system: Two 3-bladed counterrotating rotors side-by-side mounted on steel-tube outriggers. Each rotor has a diameter of 12 m. Rotor blades with steel-tube spar, wooden ribs, torsionally resistant plywood nose and fabric-covered tail; simply supported with friction damper. Automatic change-over as fly-ball governor, as with the Fw 61.

Fuselage: Framework as welded steel-tube frame, completely fabric-covered.

Empennage: Standard empennage, consisting of a complete vertical tail and stabiliser struts, mounted to the vertical fin in T-arrangement. All surfaces from fabric-covered wood.

Undercarriage: Rigid tricycle undercarriage. All wheels mounted to oil-damped shock struts. Spring-mounted auxiliary skid under the rear fuselage.

Powerplant: Air-cooled 9-cylinder rotary engine BMW-Bramo 323 Q-3 with 1x 1,000 hp take-off power, installed amidships and positively cooled. Cooling-air intake through a slit along the fuselage.

Crew: Two pilot seats side-by-side in fully glazed nose section, behind it the main cabin with another 4 seats or freight.

| Type designation: | Fa 223 “Dragon” |

| Usage: | Transport Helicopter |

| Manufacturer: | Focke-Achgelis |

| Country: | Germany |

| First flight: | 1940 |

| Length: | 12.25 m |

| Height: | 4.35 m |

| Rotor diameter: | 12 m each |

| Number of rotor blades: | 2 x 3 |

| Powerplant: | BMW-Bramo 323D |

| Power: | 1,000 hp (735 kW) |

| Max. speed: | 182 km/h |

| Service ceiling: | 2,010 m |

| Empty weight: | 3,180 kg |

| Max. take-off weight: | 4,434 kg |

| Range: | 300 km |

| Crew: | 1 |

| Manufactured: | 20 |

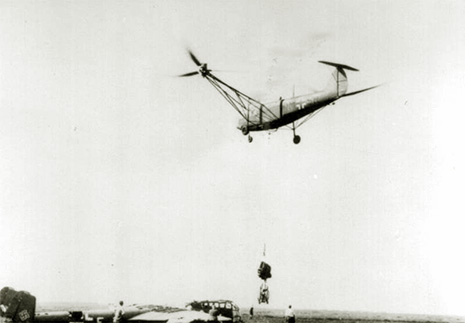

Focke-Achgelis Fa 330 “Wagtail”

Exhibit in the Museum

In spring 1942, this small unpowered rotary-wing aircraft was designed and produced within a few months. It was designed to provide an elevated observation platform while being towed behind a surfaced submarine. Because of its low wing loading of only 4 kg/m², a speed of only 30 km/h was sufficient to generate lift for the aircraft to be towed by the submarine like a kite. The airframe was as simple as possible. The fuselage consisted of a steel tube with nearly rectangular-shaped horizontal and vertical fins at its tail. Behind these fins a vane-type rudder was mounted. The rotor was controlled by tilting the head. It had a diameter of 7.31 m and consisted of three blades that were mutually braced. The rotor was mounted on a second steel tube, which stood on the first tube slightly inclined forward and mounted the pilot’s open seat. For taking off and landing, the Fa 330 used two small skids. The prototype was tested as a complete unit in the Chalais-Meudon wind tunnel that proved the usability of the aircraft. By spring of 1942, the Focke-Achgelis development department had been relocated to Laupheim because of ongoing air strikes. Nevertheless, serial production was started in the Delmenhorst plant, because the light aircraft could easily be carried to the basement in case of an air raid warning. More than one hundred Fa 330 were produced. When used on a submarine, the aircraft could be folded and stored in two metal tubes that were stowed in the submarine’s conning tower or inside the submarine and that could be watertight sealed. One tube contained the rotor head with the three blades, the other the fuselage. It took seven minutes from opening the tube cover to starting the rotor to assemble the Fa 330. Disassembling was done within two minutes. Should the submarine come under attack and need to ‘crash’ dive, the aircraft was provided with some other remarkable features. The rotor could be thrown off before touching the water surface so that the pilot was not hurt in the water by the turning rotary wings. There was a parachute built in for being used from higher altitudes. This parachute carried the remainder of the aircraft with a weight of about 40 kg down together with the pilot. The pilot had to release his belts only after touching the surface of the water. Pilots also received their basic training in the Chalais-Meudon wind tunnel using a rubber-padded launching base. A number of Fa 330 was equipped with a 2-wheel undercarriage. They served advanced training purposes at the Gelnhausen-Rothenbergen airbase using a cable launch procedure or behind an automobile. In another training section the aircraft was towed by a fast motorboat with a launching base mounted at its aft. The Fa 330 came into submarine service on the “Monsun” East Indies boats of the German Kriegsmarine. These boats of the IX D 2 type had a length of 87.6 m and a total water displacement of 1,804 m³.